WHAT IS MATERIAL HANDLING ?

materials handling, noun: the loading, unloading, and movement of goods, as within a factory or warehouse, especially by the aid of mechanical devices.(1)

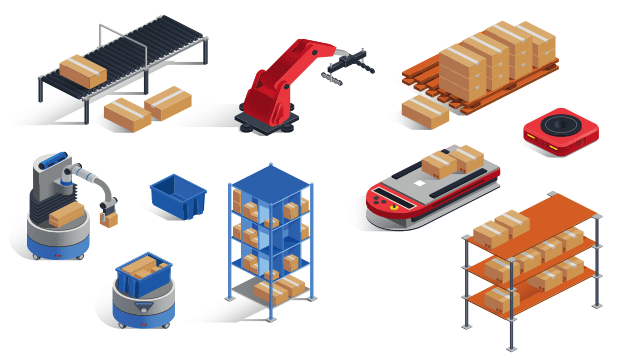

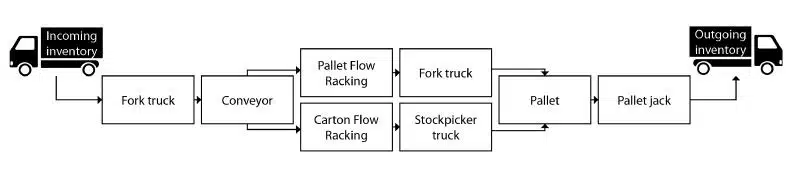

Material handling is much more than the handling of inventory. It’s the movement, protection, storage and control of materials and products throughout their lifespan of manufacturing, warehousing, distribution, consumption, and disposal. Material handling encompasses a range of components to keep the supply chain running. This includes a variety of equipment types (manual, semi-automated, and automated) and systems (single-level storage, multi-level storage, conveyors, etc.).

Efficiency is the name of the game when structuring your material handling system. Efficient logistics are a necessity when reacting to and planning for customer and warehouse requirements. Because inbound inventory’s material handling processes are just important as outbound’s processes.

Material handling process has four dimensions that impact efficient product flow through your warehouse: Movement, Time, Quantity, Space

-

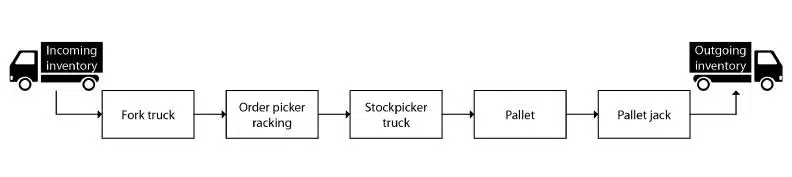

- Movement: moving product from Receiving to Outgoing

- >>Small scale example: using a fork truck to move inventory from storage onto a truck for shipment <<

- >>Large scale example: using a conveyor system to move inventory around a 100,000 sq ft distribution center <<

- Time: how long products live in storage, receipt of inventory-to-shipment time frame

- Quantity: how much product can be storage in the allotted space

- Space: how much space is allotted or available

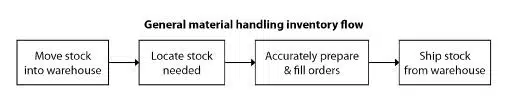

Material handling improves efficiency by making the logistics system respond quickly and effectively to plant and customer requirements. For efficient movement of goods into the warehouse, locating stock, accurately filling orders, and rapidly preparing orders for shipment to customers. Materials handling is very important to outbound logistics. In inbound logistics terms, materials handling serves company plants in the same way. Firms need to integrate materials handling requirements not only for the company’s departmental needs, but also for meeting their customers’ needs.

Latest Posts

Hợp tác trong lĩnh vực kinh tế thương mại…

Recently, Mr. Nguyen Van Danh - Vice Chairman of…

In 2023, Binh Duong province was allocated 21,817 billion…

News

- Industry Updates

NEWS